Carbon Fibre Bicycle Frame

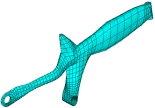

The objective was to investigate the use of structural optimisation as a design tool for the construction of a carbon fibre bicycle frame. A frame was modeled as a free form monocoque structure with single sided installation of the rear wheel. The aim was to reduce the very high vertical stiffness of a traditional diamond frame while increasing lateral and torsional stiffness. Weight was to be minimised but with all previous strength requirements still fulfilled.

The objective was to investigate the use of structural optimisation as a design tool for the construction of a carbon fibre bicycle frame. A frame was modeled as a free form monocoque structure with single sided installation of the rear wheel. The aim was to reduce the very high vertical stiffness of a traditional diamond frame while increasing lateral and torsional stiffness. Weight was to be minimised but with all previous strength requirements still fulfilled. The Carbon Fibre Bicycle project was initiated as a Master of Science (MSc) thesis work at the Department of Aeronautics, The Royal Institute of Technology, Stockholm. ALFGAM Optimering supplied the optimisation software and also participated in the actual calculations.

The Carbon Fibre Bicycle project was initiated as a Master of Science (MSc) thesis work at the Department of Aeronautics, The Royal Institute of Technology, Stockholm. ALFGAM Optimering supplied the optimisation software and also participated in the actual calculations.A total of 112 design variables were used in the combined shape and lay-up optimisation. Five different load cases were used simultaneously with a number of deflection constraints to control frame behavior. The calculations indicated advantageous increase in torsional and lateral stiffness (by a factor of 1.5) and decrease in vertical stiffness (by a factor of 5) in comparison to the reference frame.

Weight was lowered from 2.00 kg to 1.4 kg. A manufactured prototype of the frame complied well with calculated results.