Aligned C-Frame

An ACF must be perfectly balanced to assure its superior characteristics. For this very large 980x170 mm C-frame an appropriate design was impossible to achieve by hand. In cases like this ROpt is unbeatable as a design tool.

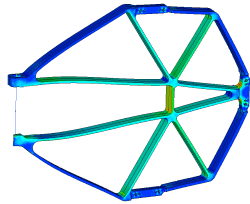

An ACF must be perfectly balanced to assure its superior characteristics. For this very large 980x170 mm C-frame an appropriate design was impossible to achieve by hand. In cases like this ROpt is unbeatable as a design tool.The FE-model of the ACF was imported to ROpt and 26 design variables were applied to the structure. Some of the variables controlling the beam nodes can be seen as red arrows to the left. Constraints were set on stresses in the material and on angular and vertical deflection of the jaws. The objective function of the optimisation was set to minimise the weight of the frame.

By using structural optimisation an almost impossible design problem was solved. The optimised ACF to the right measures 1.5x1.1 m externally at a weight of only 109 kg. The jaws of the optimised ACF has a vertical opening of 6 mm and zero angular misalignment at 55 kN load. Stresses are sufficiently low to guarantee infinite fatigue life.

By using structural optimisation an almost impossible design problem was solved. The optimised ACF to the right measures 1.5x1.1 m externally at a weight of only 109 kg. The jaws of the optimised ACF has a vertical opening of 6 mm and zero angular misalignment at 55 kN load. Stresses are sufficiently low to guarantee infinite fatigue life.